Understanding Cinder Block Weights

Cinder blocks are a staple in construction. They’re versatile, durable, and, surprisingly, variable in weight. The weight of a cinder block can range from a light 15 lbs (7 kg) to a hefty 52 lbs (23.5 kg). This variation is due to several factors, including the block’s size, whether it’s solid or hollow, and the materials used in its creation.

Size Matters

Cinder blocks come in a variety of sizes. The most widely used size is 8 inches x 8 inches x 16 inches. Naturally, the larger the block, the heavier it is. For instance, a half cinder block, measuring 8 inches x 8 inches x 8 inches, weighs approximately 18 pounds (8 kg).

Solid vs Hollow

Cinder blocks can be either solid or hollow. Hollow blocks are more common and lighter than their solid counterparts. They also offer benefits such as improved insulation and space for structural support elements. A two-hole hollow cinder block can weigh between 24 and 52 pounds (7 and 23.5 kg).

Material Weight

The material used to create cinder blocks also affects their weight. Cinder blocks are made from a mix of concrete and coal cinders, both heavy materials.

However, the weight of a cinder block can vary depending on the proportions of these materials used.

Weight Standards

Interestingly, cinder block weights are standardized in some regions. For example, in the USA, a cinder block has a standard weight of approximately 16 kg. This standardization helps ensure consistency in building projects.

Comparisons

Compared to other building materials, cinder blocks are lighter than concrete blocks of the same size. They’re also lighter than bricks, which are typically heavier.

Understanding the weight of cinder blocks is crucial when planning a construction project. It affects logistics costs, project completion time, and labor requirements. Lighter blocks are easier to transport, quicker to install, and require less manpower.

So, before you start your next construction project, take a moment to consider the weight of your cinder blocks. It might seem like a small detail, but it can have a big impact on your project’s success. For more information on cinder blocks and other construction materials, check out Happho, a one-stop solution for all your construction needs.

Remember, knowledge is power. The more you know about your materials, the better prepared you’ll be for your project. Happy building!

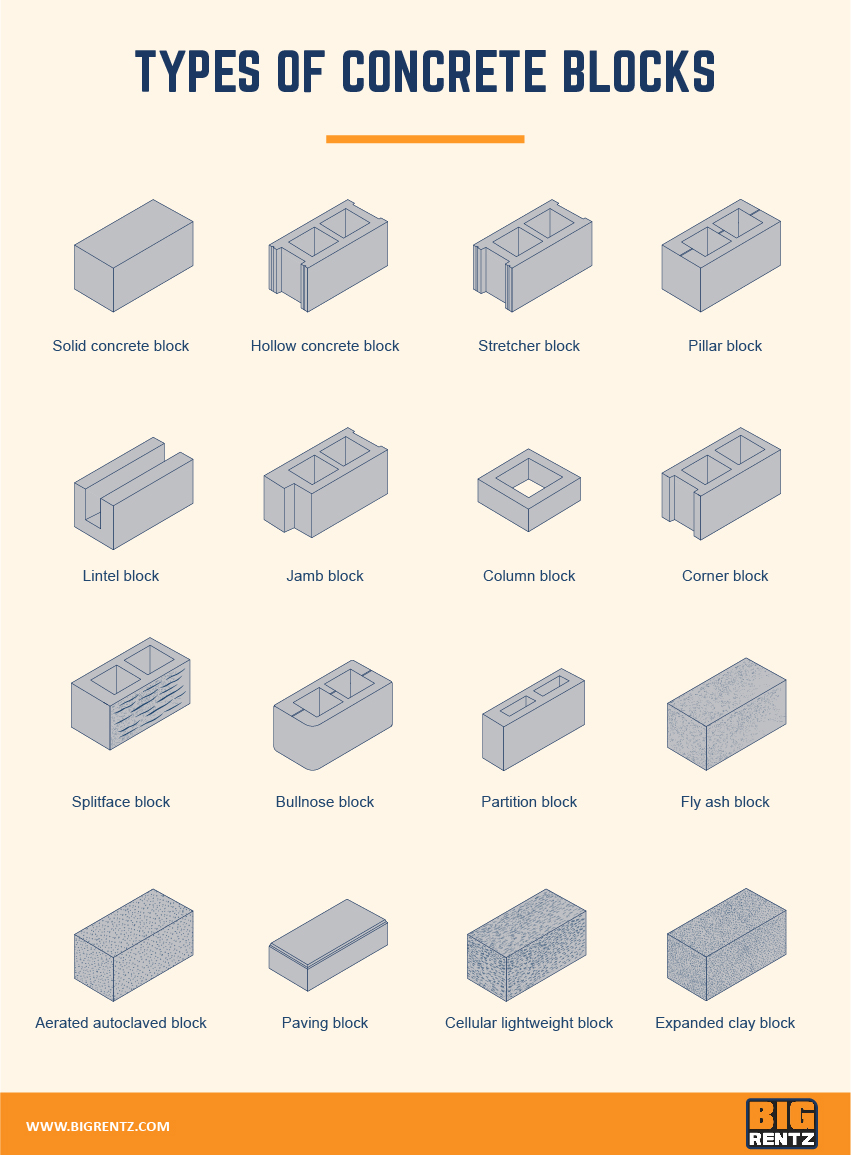

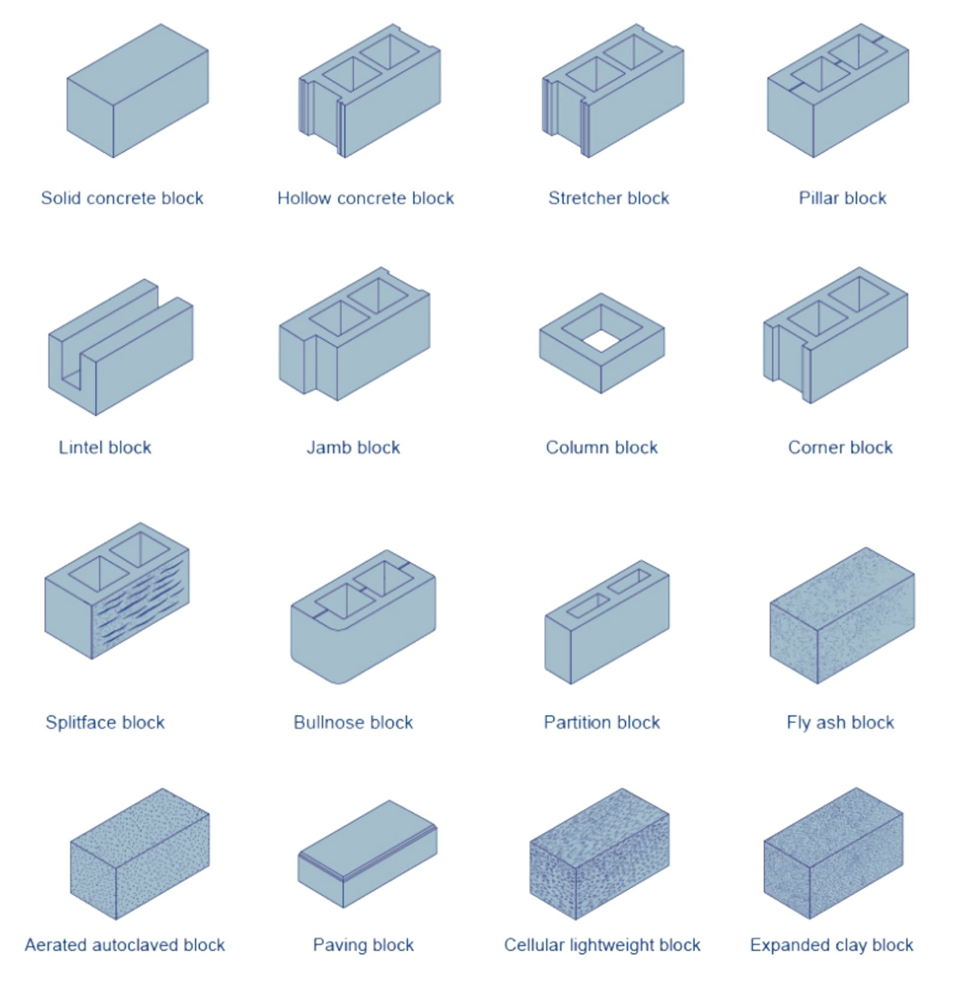

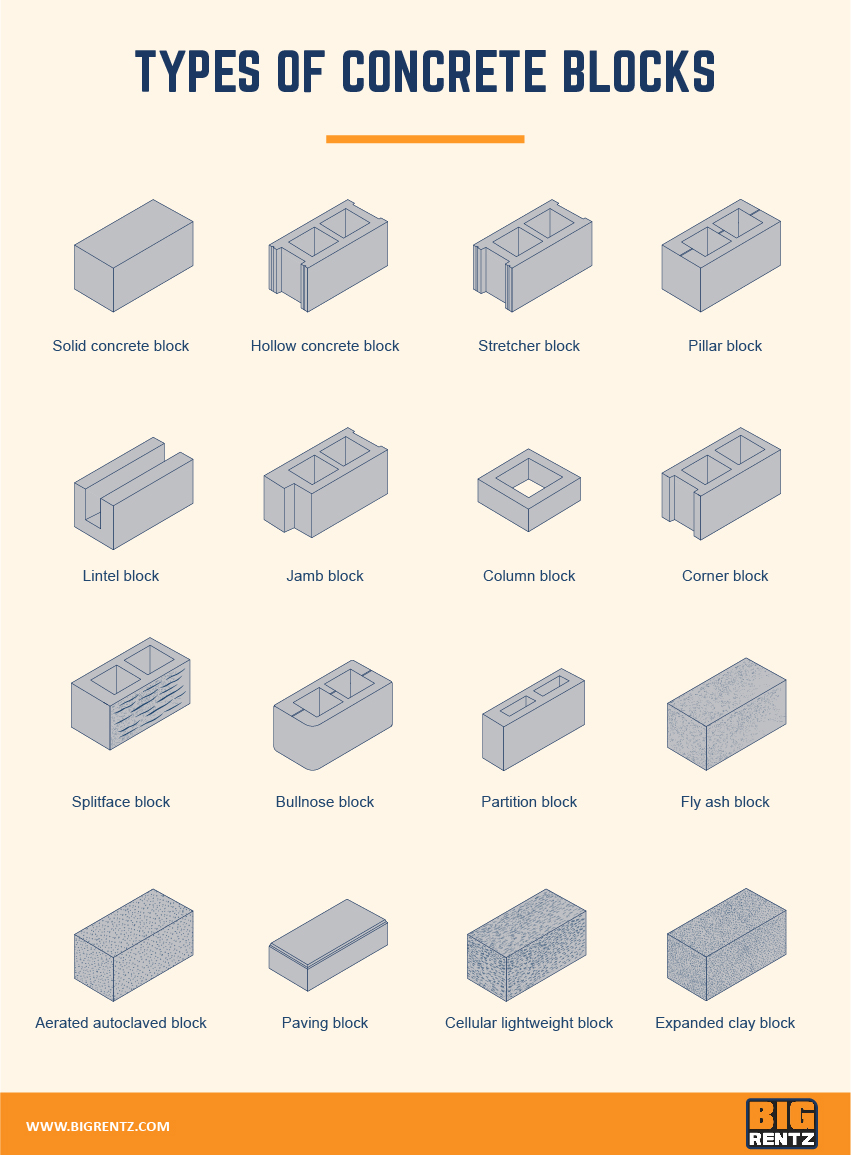

Different Types of Cinder Blocks and Their Weights

When it comes to construction, the type of cinder block you choose can make a significant difference. Let’s delve into the different types of cinder blocks and their weights.

Understanding the Basics

Cinder blocks, also known as concrete masonry units (CMUs), come in a variety of shapes and sizes. The most common size is the standard 8 inches x 8 inches x 16 inches block. This block typically weighs around 16 kg. However, the weight can vary from 10.9 kg to 20.1 kg, depending on whether the block is hollow or solid.

Hollow vs Solid Cinder Blocks

Hollow cinder blocks are lighter than solid ones. They have one or two holes, reducing their weight and providing space for structural support elements. A two-hole hollow cinder block can weigh between 24 and 52 pounds (7 and 23.5 kg).

On the other hand, solid cinder blocks are heavier but offer more strength and durability. They’re ideal for applications requiring robustness, such as foundation walls.

Specialty Cinder Blocks

There are also specialty cinder blocks designed for specific construction needs. For instance, bullnose blocks have a rounded edge, making them perfect for corners.

Lintel blocks have a U-shaped design, allowing for the insertion of horizontal reinforcements.

Each of these specialty blocks has a different weight, so it’s essential to consider this when planning your construction project.

Cinder Blocks vs Other Building Materials

Compared to other building materials, cinder blocks are lighter than concrete blocks of the same size. They’re also lighter than bricks, which are typically heavier.

For example, a standard clay brick weighs around five pounds, while an 8-inch concrete block can weigh as much as 43 pounds. Autoclaved aerated concrete (AAC) blocks, on the other hand, weigh around 80 percent less than traditional blocks.

Choosing the Right Cinder Block

Choosing the right cinder block for your project depends on various factors, including the block’s weight. Lighter blocks are easier to transport and install, reducing labor costs and project completion time.

However, heavier blocks offer more strength and stability, making them suitable for load-bearing walls and foundations.

To make an informed decision, consider consulting with a construction expert or a reputable company like Home Depot. They can provide valuable advice based on your specific construction needs.

Remember, the success of your construction project hinges on the materials you choose. So, take the time to understand the different types of cinder blocks and their weights. It’s a small detail, but it can make a big difference. Happy building!

Calculating the Number of Cinder Blocks Needed for a Project

Planning a construction project? Knowing how many cinder blocks you need is crucial. It’s not rocket science, but it does require some basic math. Let’s break it down.

Step 1: Measure Your Wall

First, measure the length and height of your wall in inches. Multiply these numbers to get the total square footage. For example, if your wall is 120 inches long and 96 inches high, your total square footage is 11,520 square inches.

Step 2: Calculate the Size of One Block

Next, calculate the size of one cinder block. The standard size is 16 inches long by 8 inches high. So, the total square footage of one block is 128 square inches.

Step 3: Divide and Conquer

Now, divide the total square footage of your wall by the size of one block. This will give you the number of blocks you need. Using our example, 11,520 divided by 128 equals 90. You’ll need 90 cinder blocks for your wall.

Step 4: Plan for Contingency

But wait, don’t rush to the store just yet. It’s wise to buy a few extra blocks. Why? Well, accidents happen. Blocks can break during transport or installation. Also, your measurements might not be 100% accurate. So, add a contingency of 5% to 10% to your total.

In our case, that’s 4 to 9 extra blocks.

Step 5: Shop Smart

Now you’re ready to shop. But where? Check out Survival Freedom for a list of the cheapest places to buy cinder blocks.

Remember, the cost of cinder blocks can vary. It depends on the quality and type. On average, you can expect to pay between $1 and $5 per block. So, shop around to get the best deal.

Step 6: Consult an Expert

Finally, if you’re unsure about anything, consult an expert. Companies like Home Depot can provide valuable advice. They can help you choose the right cinder block for your project and even assist with calculations.

There you have it. A simple guide to calculating the number of cinder blocks you need for your project. Remember, planning is key. The more accurate your calculations, the smoother your project will go. So, take your time, measure twice, and build once. Happy construction!

Load Bearing Capacity of Cinder Blocks

Cinder blocks are a staple in construction. They’re versatile, affordable, and easy to work with. But, have you ever wondered how much weight these blocks can bear? Let’s dive into the fascinating world of cinder block load bearing capacity.

What Influences Load Bearing Capacity?

The load bearing capacity of cinder blocks is influenced by several factors. Size, shape, and ingredients play a key role. A standard cinder block, measuring 16 inches long by 8 inches high, can support at least 1,700 pounds per square inch (PSI). This is according to ASTM standards, a trusted source for technical standards for materials, products, systems, and services.

Weight distribution and structural context also impact load bearing capacity. A block under uniform pressure can bear more weight than one under concentrated load.

Material Matters

The material used in construction also affects load bearing capacity. Blocks made with stone dust often support more weight than those made with sand. The quality of the cement and aggregates used in making the block also affects its strength.

Reinforcing Bars (Rebars)

Reinforcing bars, or rebars, can increase the load-bearing capacity of concrete slabs. These steel bars are placed within the concrete to resist tensile forces, allowing the concrete to bear more weight. Proper spacing of rebars is crucial for effective reinforcement.

Variables such as maximum load, soil bearing capacity, rebar diameter, and slab grade influence rebar spacing.

Hollow vs. Solid Blocks

Hollow cinder blocks are usually weaker than solid ones. The hollow spaces reduce the amount of material, and hence, the load-bearing capacity. However, these blocks are lighter and easier to handle, making them ideal for non-load-bearing walls or partitions.

Quality Control

The storage method, consistency testing, and quality of water used in making the cinder blocks are important factors. Companies like Home Depot ensure strict quality control to provide blocks that meet the required standards.

Know Your Blocks

Knowing the weight capacity of cinder blocks is vital for construction projects and safety. Overloading a block can lead to structural failure, posing a risk to people and property. Always consult an expert if you’re unsure about the load-bearing capacity of your blocks.

In a nutshell, the load bearing capacity of cinder blocks is influenced by a myriad of factors. Understanding these can help you make informed decisions in your construction projects. Remember, safety first!

Practical Uses and Costs of Cinder Blocks

Cinder blocks are a jack-of-all-trades in the construction world. They’re versatile, affordable, and easy to work with. But, they’re not just for building walls and foundations. You can use them to create a variety of structures. From TV stands and nightstands to fire pits and living walls. Even birdhouses, fences, and wine cellars. The possibilities are endless!

Cost-Effective Construction

The cost of a cinder block is generally $1 to $3 each. It’s a small price to pay for such a versatile material. Plus, they offer advantages like better insulation, fire resistance, and durability. They’re also lighter and cheaper than concrete blocks. This makes them a popular choice for many construction projects.

Building a cinder block wall? Expect to pay between $15 to $30 per square foot. This includes both materials and professional labor costs. But, don’t fret. There are ways to reduce these costs.

Money-Saving Tips

First, cinder blocks require less mortar and plastering. This can save you a significant amount of money. Second, consider doing some of the work yourself. Laying cinder blocks is a skill that can be learned. With a bit of practice, you could save on labor costs.

Another tip is to buy in bulk. Many suppliers offer discounts for large orders.

So, plan your project well and buy all your blocks at once.

Getting Creative with Cinder Blocks

Cinder blocks aren’t just for construction. They’re also great for DIY projects. Cinder block gardens, for example, are a space-efficient solution for growing vegetables and flowers. They’re easy to set up and require minimal maintenance.

You can also use cinder blocks to create unique furniture pieces. With a bit of creativity, you can transform these humble blocks into stylish and functional items.

Sealing and Painting Cinder Blocks

To protect your cinder block structures, consider sealing and painting them. This not only enhances their durability but also improves their aesthetic appeal.

Painting cinder blocks can be challenging, but it’s doable. The process involves cleaning, priming, and painting. Andre Kazimierski, a painting specialist, provides useful guides on painting cinder blocks. You can find his interviews and more resources at the provided URL link.

Quality Matters

Lastly, remember that not all cinder blocks are created equal. The quality of the blocks can greatly affect their performance and longevity. Companies like Home Depot ensure strict quality control to provide blocks that meet the required standards.

In the end, knowing your blocks and how to use them can make your construction projects more successful and cost-effective. So, get creative, save money, and build with confidence!